Understanding DG Transformers

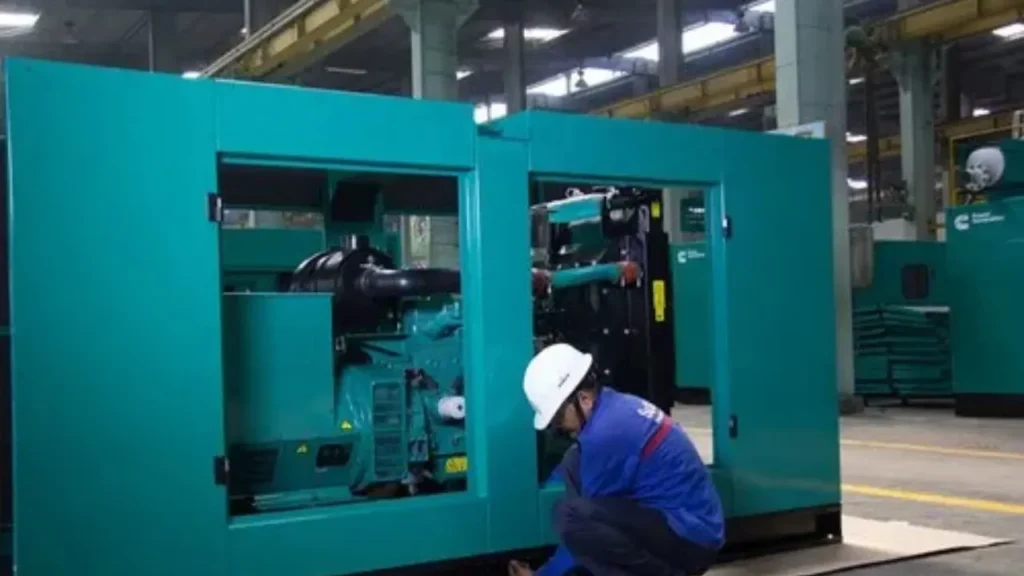

Diesel Generator (DG) transformers play a crucial role in power generation and distribution. They are used to step up or step down voltage levels, ensuring efficient energy transmission. In industries and power plants, DG transformers are essential for managing electrical loads and maintaining a stable power supply.

What is a DG Transformer?

A DG transformer is an electrical device that regulates voltage in a diesel generator system. It converts high-voltage electricity into usable power for industrial or commercial applications. These transformers are widely used in backup power systems, ensuring smooth operation during power outages.

Key Components of DG Transformers

- Core: The magnetic component that helps in efficient energy transfer.

- Windings: Copper or aluminum coils that carry the electrical current.

- Cooling System: Maintains optimal temperature during operation.

- Insulation System: Prevents short circuits and enhances durability.

Working Principle of DG Transformers

DG transformers operate on the principle of electromagnetic induction. When a diesel generator produces electricity, the transformer regulates voltage based on the application.

- Step-Up Transformer: Increases voltage for long-distance transmission.

- Step-Down Transformer: Decreases voltage for safe use in commercial settings.

Types of DG Transformers

1. Step-Up DG Transformer

This type increases voltage levels and is commonly used in power plants. It reduces power loss over long distances.

2. Step-Down DG Transformer

Used in industrial and commercial applications to lower voltage for equipment safety.

3. Isolation Transformer

This transformer prevents direct current (DC) from interfering with alternating current (AC) power systems.

4. Auto-Transformer

A single-winding transformer that adjusts voltage efficiently and is compact in size.

Applications of DG Transformers

DG transformers have various applications across industries, including:

- Power Plants: Ensures proper voltage regulation for electricity generation.

- Manufacturing Units: Provides stable power supply to heavy machinery.

- Commercial Buildings: Supports emergency backup power systems.

- Data Centers: Prevents power disruptions in critical IT infrastructure.

Benefits of Using DG Transformers

DG transformers offer multiple advantages, such as:

✔ Improved Efficiency: Reduces energy loss and enhances power distribution.

✔ Voltage Regulation: Ensures stable voltage supply.

✔ Durability: Designed for long-term operation with minimal maintenance.

✔ Safety: Prevents electrical hazards and overloads.

Maintenance and Safety Tips

Regular maintenance is essential to ensure optimal performance and longevity of DG transformers. Here are some key maintenance tips:

1. Routine Inspections

Check for overheating, loose connections, and oil leaks.

2. Cooling System Maintenance

Ensure proper functioning of fans and cooling oil levels.

3. Insulation Testing

Periodically test insulation resistance to prevent electrical failures.

4. Load Testing

Monitor transformer load capacity to avoid overloading.

The Challenges of DG Transfer

DG transfer can be a complex process. Some of the challenges that organizations face include:

- Data security: Organizations need to ensure that their data is secure during the transfer process.

- Data privacy: Organizations need to comply with data privacy regulations when transferring data.

- Data quality: Organizations need to ensure that the quality of their data is maintained during the transfer process.

- Data accessibility: Organizations need to ensure that their data is accessible after the transfer process.

- Cost: DG transfer can be a costly process.

The Future of DG Transfer

DG transfer is a rapidly evolving field. As new technologies are developed, DG transfer will become even more important. Some of the trends that are likely to shape the future of DG transfer include:

- The rise of cloud computing: Cloud computing is making it easier for organizations to store and manage data. This is likely to lead to an increase in the use of cloud-based DG transfer solutions.

- The increasing importance of data privacy: As data privacy regulations become more stringent, organizations will need to take steps to ensure that their data is protected. This is likely to lead to an increase in the use of DG transfer solutions that are designed to comply with data privacy regulations.

- The increasing use of artificial intelligence (AI): AI is being used to automate a number of tasks, including DG transfer. This is likely to lead to an increase in the use of AI-powered DG transfer solutions.

Types of Pole Mounted Transformers

Pole mounted transformers come in different forms, catering to varying needs in electric power distribution systems. Understanding the types of pole mounted transformers helps us see their functions better in managing electrical systems and distributing energy efficiently.

Single-Phase Transformers

Single-phase transformers carry electricity to smaller areas with low power demands. They are a type of distribution transformer that steps down high-voltage electricity to a usable voltage suitable for homes and small businesses.

Single-phase transformers are efficient and offer reliable service by reducing high primary voltages to secondary voltages, which is safe for everyday use. They are simple, making them cost-effective and easier to maintain. They are ideal for residential areas and small industries where the power demand is not as significant.

Three-Phase Transformers

Three-phase transformers serve a different purpose than single-phase transformers. They are necessary for areas that need more electricity, such as larger businesses and industrial areas.

Three-phase transformers have greater capacity. They help distribute larger amounts of electricity, making them efficient for bigger loads and demands. They offer stability and balance. In an electric distribution system, they provide a balanced load, reducing the likelihood of transformer failures and ensuring steady electric power distribution.

They are essential in commercial buildings, factories, and large institutions due to their ability to handle high-voltage transmission lines effectively.

Comparison Table

| Features | Single-Phase Transformers | Three-Phase Transformers |

|---|---|---|

| Complexity | Simpler design, smaller use cases | More complex, suitable for industrial use |

| Cost | Lower due to smaller size and capacity | Higher due to increased materials and labor |

| Capacity | Lower | Higher |

| Application | Homes and small businesses | Large businesses, industries |

Both types of transformers play a significant role in electric distribution systems. They efficiently manage electrical energy and bring innovation to electric power distribution systems.

By understanding their applications and advantages, we can appreciate how pole mounted transformers help keep our neighborhoods and businesses powered safely and reliably.

Uses of Pole Mounted Transformers

Residential Use

In neighborhoods, pole mounted transformers take electricity from high-voltage transmission lines and turn it into usable voltage for homes. Single-phase transformers are designed to handle one electric current at a time, making them perfect for residential areas.

Residents rely on pole mounted transformers to power everything from lights to refrigerators. They step down the high-voltage electricity to a secondary voltage level that’s suitable for household use. The process involves primary and secondary winding, where the high voltage is reduced to a lower, safer voltage.

One of the great things about pole mounted transformers is that they are very reliable. They are designed to provide a steady electric supply, minimizing the risk of power interruptions. A well-maintained transformer will last many years, supporting families’ everyday needs.

Industrial Use

In industrial settings, pole mounted transformers have a slightly different but equally important role. Many factories and businesses require more power than a typical home. Here, pole mounted transformers are used for their ability to supply increased power through robust distribution transformers.

Industries often use three-phase transformers, another specialized type of pole mounted transformer. These transformers keep factories running smoothly by:

- Providing reliable energy for machinery

- Adjusting voltage to fit the demanding needs of industrial equipment

- Minimizing energy losses during power transfer over utility poles

Key Components of Pole Mounted Transformers

Core

The core is fundamental to the operation of every pole-mounted transformer. It helps transfer electrical energy between circuits. The core is usually made of laminated steel sheets stacked together to form a strong magnetic field. The core minimizes energy loss and increases transformer efficiency, ensuring steady power delivery.

Windings

Windings are another vital part of pole mounted transformers. These copper or aluminum wires wrap around the core and include two types: primary winding and secondary winding.

- Primary winding connects to the high-voltage transmission lines, receiving high-voltage electricity directly from the power grid.

- Secondary winding reduces this primary voltage to a safer secondary voltage level for customers.

Windings are responsible for receiving and transforming energy by converting high-voltage to low-voltage, making energy usable for homes and businesses. They also ensure safety by lowering voltage levels, preventing electrical hazards and transformer failures.

Tap Changers

Tap changers adjust voltage levels to ensure a stable power supply even when the input voltage changes. They make these adjustments by switching connections between various points in the winding or taps. Tap changers offer stability and adaptability, maintaining a consistent voltage suitable for end-users and adjusting output voltage levels as needed.

Grounding Requirements for Pole Mounted Transformers

Grounding pole mounted transformers ensures safety and reliability when delivering power.

Grounding is about safety. It protects against electric shock by providing a path for stray electrical currents. It helps prevent faults and reduce transformer failures. Proper grounding maintains voltage levels, ensuring they stay within safe limits. Grounding absorbs excess energy from lightning or power surges, protecting the transformer.

Table: Grounding Benefits

| Benefit | Description |

| Safety | Reduces shock risk |

| Reliability | Prevents transformer failures |

| Voltage Regulation | Keeps voltage suitable for use |

| Surge Protection | Defends against power surges |

Proper grounding of pole mounted transformers supports a reliable, innovative, and customer-centric electric distribution system. It ensures transformers perform their primary function of delivering usable voltage efficiently and safely.

Installation Standards and Best Practices

When installing pole mounted transformers, adhering to specific standards and best practices is important for safety and efficiency.

Proper Sizing

Ensure the transformer size matches the intended load to prevent transformer failures. Use the formula ( Power = Voltage × Current ).

Location

Install transformers on sturdy utility poles away from obstacles like tree branches and buildings to prevent accidents and ensure easy access.

Grounding

Proper grounding is vital to protect against electrical faults. Always connect the transformer’s grounding wire to a grounding rod.

Weatherproofing

Seal all entry points against moisture. Liquid-filled transformers require regular inspections to avoid leaks.

Clearance

Maintain adequate clearance from high-voltage transmission lines to ensure safety and minimize magnetic field interference.

By following these guidelines, transformers operate reliably and efficiently within electric distribution systems.

Maintenance Practices for Optimal Performance

To ensure optimal performance of your pole mounted transformers in electric distribution systems, regular maintenance matters. Key practices include:

- Visual inspections: Check for visible damage, leaks, or corrosion. Look for overheating or unusual noise.

- Cleaning: Keep transformers free from debris and dust to prevent overheating.

- Oil analysis: Test oil in liquid-filled transformers for moisture, oxidation, and dissolved gases.

- Tightening connections: Secure electrical connections to prevent arcing.

- Thermal imaging: Use thermal imaging to detect hot spots, which indicate overload or other issues.

- Load assessment: Monitor electrical loads to prevent overloading.

- Regular testing: Conduct insulation resistance, winding resistance, and turns ratio tests.

By following these maintenance practices, you’ll enhance transformer performance and longevity while minimizing failures.

Get Your Pole Mounted Transformers from UTB Transformers

Pole-mounted transformers are essential for efficient and reliable power distribution in modern electrical systems. At UTB Transformers, we provide high-quality pole-mounted transformers designed to meet today’s infrastructure demands.

If you’re looking for top-tier transformers to enhance your distribution system, trust UTB Transformers for all your needs. Contact UTB Transformers today to learn more about our range of products and ensure uninterrupted power delivery.

Let UTB Transformers be your go-to partner in building a more reliable electrical grid.

Essential Maintenance Tips for Industrial Transformers

The Importance of Transformer Maintenance

When it comes to industrial operations, the reliability of your equipment can make or break your success — and that includes industrial transformers. These crucial components help ensure a smooth and steady flow of electricity, which is essential for many industries. Keeping transformers in top shape is vital for both safety and efficiency.

Transformers are complex machines that require diligent care and attention. Regular maintenance enhances their lifespan and minimizes the risk of dangerous malfunctions. Understanding the importance of routine inspections, proactive strategies, and effective monitoring significantly impacts transformer safety and performance in the long run.

In this article, we will explore essential maintenance tips to ensure the longevity of your industrial transformers. We’ll cover various strategies, from conducting routine checks to troubleshooting common issues, all aimed at preserving the integrity and safety of your transformers.

Regular Oil Checks: What to Look For

Regular oil checks are essential for maintaining the health of your industrial transformers. A key factor to monitor is the oil level, as it directly affects the transformer’s cooling and insulation properties. Ensuring the oil is at the appropriate level helps support optimal performance and prevent costly repairs.

Another vital aspect is checking the oil condition, including its dielectric strength and moisture content. Your transformers need high dielectric strength for insulation to prevent breakdowns. Additionally, monitoring moisture content is important, as excess moisture may lead to transformer failure and insulation breakdown.

During regular inspections, look for any signs of oil leakage around the drain valve or other transformer components. Such leaks may indicate potential issues needing immediate attention.

Comprehensive Testing Procedures

Comprehensive testing procedures ensure your equipment’s efficiency and safety. These tests help identify potential issues before they become costly problems. The process generally includes several vital steps to verify the system’s reliability.

First, visual inspections help spot obvious defects or damages. Next, performance tests measure if the equipment meets the required specifications. After that, electrical testing checks for any faults or irregularities in the system’s electrical flow.

Include functional testing, which examines whether all components work correctly together. Finally, environmental tests check the equipment’s operation under different conditions, such as temperature and humidity.

Together, these steps make up a robust testing procedure that ensures optimal performance and minimizes risks. By following these procedures, companies can maintain a high standard for their equipment and overall operations.

Optimizing Load Management for Reliability

To optimize load management, it is essential to monitor power demand and adjust it to match the system’s capacity. This prevents sudden outages and extends the lifespan of your equipment.

Utilizing smart meters and real-time data analysis can significantly assist in optimizing load management. These tools provide insights into consumption patterns, allowing for better scheduling of high-demand operations. Shifting non-essential loads to off-peak times is another effective strategy, helping balance the load and reduce peak demand charges.

Incorporating load management systems also contributes to energy conservation and cost savings. These systems automatically adjust loads in response to demand, ensuring optimal performance and efficiency.

Implementing these measures supports reliable operations and minimizes the risk of transformer failure and costly repairs. By consistently managing the load effectively, businesses can ensure a healthier and more reliable power infrastructure.

Maintain your transformers with UTB Transformers

Proper maintenance is critical to ensuring the longevity and efficiency of your industrial transformers. At UTB Transformers, we offer expert guidance and services to help keep your equipment running smoothly. Our comprehensive maintenance solutions ensure that your transformers perform at their best, minimizing downtime and reducing repair costs.

Conclusion

DG Transformers are indispensable in modern power systems, providing stable and efficient energy distribution. Whether in industrial setups, hospitals, or telecommunications, their role in ensuring uninterrupted power supply cannot be overstated.

By understanding their components, types, benefits, and maintenance, businesses can maximize transformer efficiency, reduce downtime, and enhance safety. With ongoing advancements, the future of DG Transformers looks promising, paving the way for smarter and more sustainable energy solutions.